AI Optical Navigation System

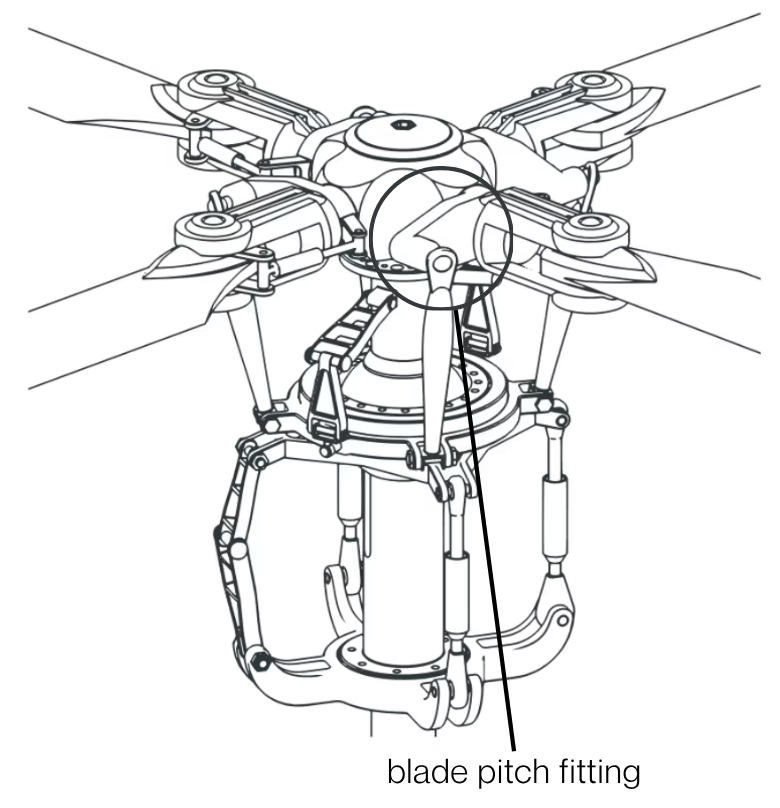

Navigate in GPS denied environment

One of my greatest achievement was to design and build a system allowing a fixed-wing UAV to navigate without GPS using optical systems in less than a month.

We managed to fly 16km with 50m precision without GPS

We used a combination of classical odometry algorithms calibrated with AI image recognition tools to cancel the drift of the dead-reckoning system

We simplified the integration to the autopilot by emulating NMEA frame